T: +86-19511798062

E: sales@honestflex.com

E: sales@honestflex.com

Licang District, Qingdao, Shandong, China

Views: 0 Author: Site Editor Publish Time: 2025-07-31 Origin: Site

Choosing the right materials for your chemical suction hose keeps things safe and running well. When you pick the right materials, your hose is safe from leaks, spills, and wearing out too soon.

The right materials help your hose stand up to strong chemicals and tough places.

You make accidents less likely and keep your team and nature safe.

Picking the right chemical suction hose also helps you follow safety rules and have less downtime.

You should always match your hose materials to the chemicals, place, and job. For the best results, check compatibility charts or ask experts before you decide.

Pick hose materials that work with the chemicals you use. This helps keep your system safe and stops leaks. Materials like UHMWPE and EPDM are strong against chemicals. They last a long time and follow safety rules. Always check the temperature and pressure limits before you buy a hose. This helps stop damage and keeps the hose working well. Hoses that bend easily and are strong save money. They last longer and fit in small or rough places. Always look at hoses often for any wear or damage. Change them right away if you see problems to stop accidents.

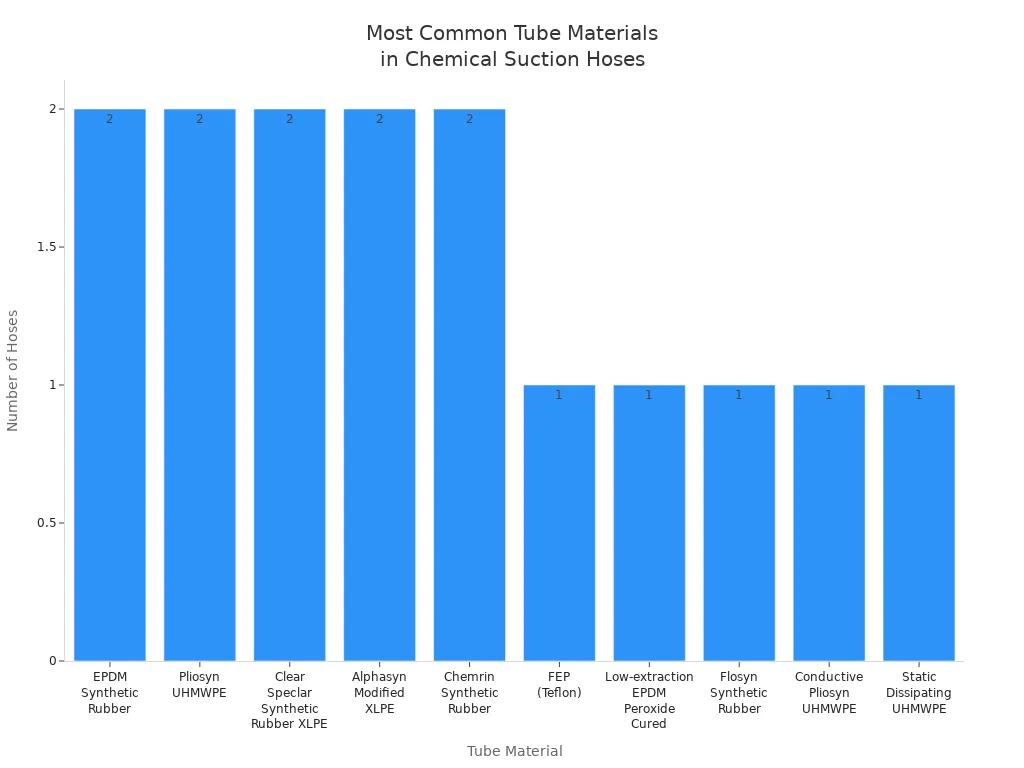

It is important to know how each material works. Every material has things it does well and things it does not. Some materials are better with certain chemicals. Others can handle heat or rough use better. The most common materials are PVC, rubber, EPDM, UHMWPE, PTFE, metal, neoprene, polyurethane, composite, and silicone. Many hoses use synthetic linings and steel wire to be stronger and safer. UHMWPE and EPDM are used a lot. They can handle many chemicals and work well for moving liquids.

Here is a simple table to help you see the good and bad parts of each material:

Material | Pros | Cons |

|---|---|---|

PVC | Lightweight, low cost, flexible | Limited chemical and temperature range |

Rubber | Good flexibility, abrasion resistance | Can degrade with some chemicals |

EPDM | Excellent weather and ozone resistance | Not suitable for oils or hydrocarbons |

UHMWPE | High chemical resistance, food safe | Less flexible than rubber |

PTFE | Handles extreme chemicals and temperatures | Expensive, less flexible |

Metal | Very strong, high temp and pressure | Heavy, can corrode, not flexible |

Neoprene | Good weather and flame resistance | Limited chemical compatibility |

Polyurethane | Abrasion resistant, flexible | Not for strong acids or bases |

Composite | Customizable, broad chemical compatibility | Can be heavy, more complex construction |

Silicone | High temp range, food safe | Not for strong acids or solvents |

Honestflex’s Chemical Suction Hose uses two layers, UHMWPE and EPDM. This special design gives great chemical resistance and lasts a long time. It also meets tough safety rules. You get a hose that works for many chemicals and is safe for food and factories.

PVC is a very common hose material. It is light and easy to move. Many people pick PVC because it does not cost much. It bends well for simple jobs. But PVC has limits you should know. It is not good for tough chemical jobs.

Property | Advantages | Disadvantages |

|---|---|---|

Flexibility | Lightweight, easier to handle than rubber | Less flexible than rubber hoses, limiting use in tight bends or frequent movement |

Chemical Resistance | Good resistance to many acids, bases, and chemicals | Sensitive to certain chemicals, oils, and solvents; prolonged exposure can cause degradation |

Temperature Range | Suitable for moderate temperatures | Becomes brittle and cracks at very low temperatures; softens or deforms at high temperatures |

Durability | Affordable and lightweight | Less resistant to physical damage and wear compared to rubber and reinforced hoses |

PVC hoses save money and work with many acids and bases. They are good for jobs that do not need high pressure or heat. PVC gets hard and cracks in cold weather. It gets soft if it gets too hot. Sunlight and strong chemicals can make PVC break or leak. Always check if your chemicals are safe for PVC. PVC does not bend as well as rubber. This makes it harder to use in tight spots.

Tip: If you see cracks, swelling, or blisters on your PVC hose, get a new one fast. These signs mean the hose is getting weak or reacting with the chemicals.

Rubber hoses are strong and bend easily. You can use them for many jobs. Rubber lasts a long time and can take rough use. It does not wear out fast, even in hard places.

Aspect | Rubber Hose | Composite Hose |

|---|---|---|

Chemical Compatibility | Limited by rubber type (e.g., EPDM, Nitrile) | Wide and customizable for specific chemicals |

Durability | Strong abrasion resistance and high pressure rating (up to 100+ bar) | Moderate abrasion resistance and pressure rating (up to 25 bar) |

Flexibility | Less flexible, heavier | Very flexible, lightweight |

Lifespan | Longer lifespan (5–10 years with care) | Shorter lifespan (3–7 years) |

Rubber hoses can take high pressure and last for years. Different rubbers work with different chemicals. Nitrile rubber is good with oils. EPDM is better for water-based chemicals. Rubber hoses are heavier than PVC. They cost more, but they last longer and resist damage better.

Note: Always check what kind of rubber you have before using it with chemicals. Some rubbers break down with some fluids.

EPDM is a special rubber. It is used in many hoses because it resists weather and many chemicals. EPDM works well with water, alcohols, and some acids. It does not work with oils or fuels.

EPDM hoses work with polar solvents and water-based fluids.

They do not crack from sunlight or ozone.

EPDM does not swell with most acids and coolants.

Do not use EPDM with petroleum fluids. It will break down.

Honestflex hoses use EPDM on the outside. This helps protect against weather and chemicals. The hose stays bendy in hot or cold places. The EPDM cover helps the hose last longer, even outside.

Honestflex hoses use both EPDM and UHMWPE. This makes the hose work well and meet food and industry rules.

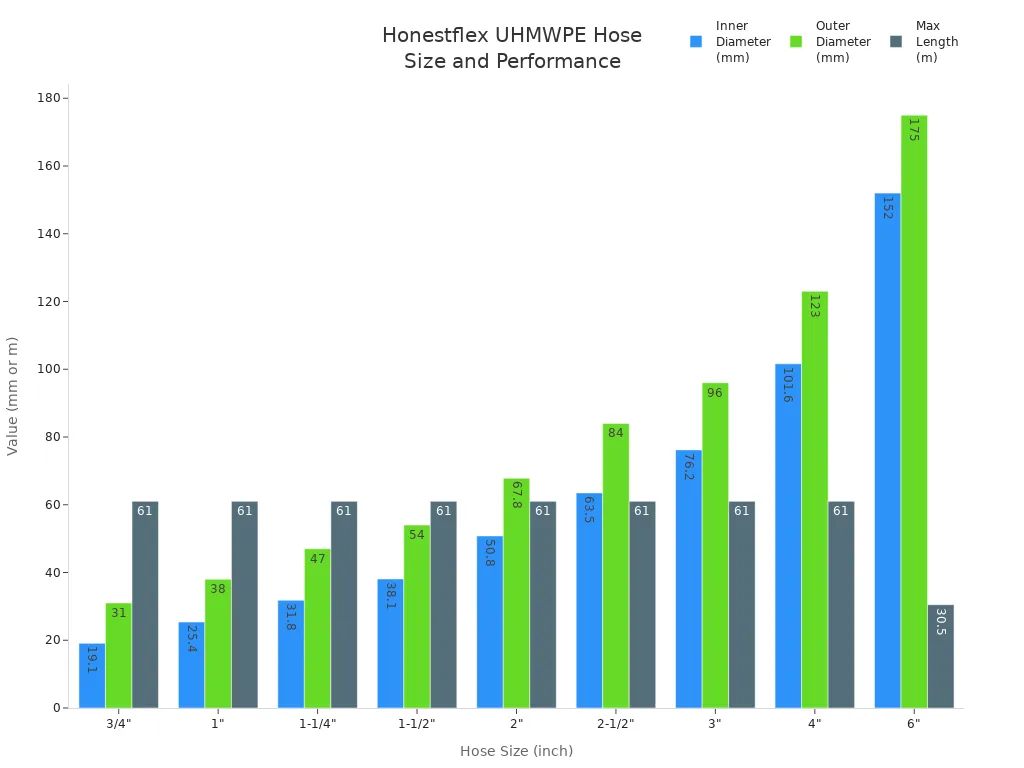

UHMWPE means Ultra High Molecular Weight Polyethylene. This material is known for great chemical resistance and food safety. You can use UHMWPE hoses for acids, bases, and solvents. You do not have to worry about leaks.

UHMWPE hoses resist strong acids and bases.

They are safe for food and drinks.

The inside is smooth, so it is easy to clean.

UHMWPE hoses last a long time and save money.

They stay bendy for tight spaces and stop leaks.

Honestflex hoses use UHMWPE inside. This gives great chemical safety and lasts long. The hose meets strict rules for food and industry. It works in very cold and hot places. The wire design stops kinks and static, making it safer.

PTFE is also called Teflon. It is one of the best hose materials for strong chemicals. You can use PTFE hoses for almost any chemical.

PTFE hoses work in very hot and very cold places. They do not react with most chemicals. This keeps your hose safe from damage. PTFE hoses are not as bendy as rubber or silicone. They can be hard to fit in small spaces. PTFE hoses cost more than other hoses. They do not work well with UV light or steam all the time.

Note: Pick PTFE hoses if you need the best chemical safety and heat range. But check if you need more bend or a lower price.

Metallic hoses are made from stainless steel or special metals. You can use them for high pressure and heat. Metallic hoses resist many chemicals and last a long time.

Metallic hoses work with strong acids and bases.

They are good for vacuum and high-pressure jobs.

You can use them for steam and very cold fluids.

Metallic hoses do not break down like plastic or rubber.

They are heavy and do not bend much.

You will see metallic hoses in oil plants and ships. They are also used for steam lines and places that need fire safety.

Neoprene is another kind of rubber. You can use neoprene hoses outside. They resist weather, ozone, and fire. Neoprene hoses work with many oils and chemicals. But they do not work with some strong chemicals.

Aspect | Advantages | Disadvantages |

|---|---|---|

Weather Resistance | Good resistance to oxygen, ozone, and weather; suitable for outdoor use | N/A |

Chemical Compatibility | Performs well with oils and many chemicals | Not compatible with aromatic hydrocarbons, chlorinated hydrocarbons, and polar solvents (ketones, esters, ethers, acetones) |

Mechanical Properties | Outstanding mechanical properties | N/A |

Fire Resistance | Good resistance to fire | N/A |

Electrical Properties | N/A | Poor electrical insulation |

Processing & Maintenance | N/A | Difficult to process and maintain |

Neoprene hoses are tough and last long outside. Do not use them with strong solvents. They are not good for electric safety.

Polyurethane hoses are known for being tough and bendy. You can use them where hoses rub or carry rough stuff.

Polyurethane hoses last up to 10 times longer than rubber.

They are harder than rubber but bend more than most plastics.

Polyurethane hoses stay bendy in cold weather.

They do not kink and are hard to tear.

You will not need to replace them often.

Polyurethane hoses are good for moving powders and pellets. They cost more than PVC but last longer, saving money.

Composite hoses have many layers of different materials. You can use them for many chemicals, even strong ones. Composite hoses bend well and can be made for special jobs.

Composite hoses work with acids, solvents, and oil products.

They are used in chemical plants and ships.

Composite hoses meet world safety rules.

They are heavier and more complex than single-material hoses.

You will see composite hoses in ship transfers and factories. They are good when you need both chemical safety and bend.

Silicone hoses are best for hot jobs. You can use silicone hoses for food, medical, and factory work. Silicone stays bendy from very cold to very hot.

Feature | Silicone Hose | Rubber Hose | PTFE Hose |

|---|---|---|---|

Temperature Range | Continuous: -60°C to 260°C; Short-term up to 315°C | Up to ~150°C | Up to 315°C (600°F) |

Flexibility | Maintains flexibility at high/low temps | Hardens/cracks over time | Less flexible than silicone |

Durability | Resistant to aging, UV, ozone | Less resistant to aging and UV | Highly durable |

Chemical Resistance | Good chemical stability; not for oils/fuels | Good with oils/fuels | Superior chemical resistance |

Cost | Moderate | Lower | Higher |

Certifications | FDA, USP Class VI, ISO | Varies | Varies |

Recommended Use | Medical, food-grade, industrial, chemical transfer (excluding oils/fuels) | Oil/fuel applications | Extreme chemical resistance needs |

Silicone hoses are not good for oils or fuels. They bend better than PTFE and last longer than rubber in heat. You can use silicone hoses for food and medical jobs because they meet strict safety rules.

You must pick hose materials that match your chemicals. Not every material works with all chemicals. Some hoses can get weak or break with strong chemicals. Always check a chemical compatibility chart before you buy. Look at what chemicals you use, how strong they are, and how long they touch the hose. Use hoses made for your chemicals to stop leaks or damage. If you work with flammable or dangerous chemicals, use hoses with double layers or antistatic parts for more safety. Honestflex hoses use special materials for strong chemical safety.

Tip: Use couplings and gaskets that can handle the same chemicals as your hose.

Temperature and pressure change how a hose works. Every hose has a safe range for both. If you go past these limits, the hose can break. EPDM and UHMWPE hoses work in hot and cold places. Check the temperature of your chemicals and where you use the hose. Make sure your hose can take the highest pressure in your system. Hoses like Honestflex have strong layers and wire to handle high pressure and keep their shape.

Parameter | Value |

|---|---|

Working Pressure | Up to 300 psi (20 bar) |

Temperature Range | -40℃ to +120℃ (-72℉ to +248℉) |

You want a hose that bends easily and lasts long. Both the material and design affect this. Spiral or helix shapes help hoses bend without folding. More layers make hoses stronger but less bendy. For outdoor or tough jobs, pick hoses with covers that block sun, weather, and scratches. Honestflex hoses are both flexible and tough, so they fit in small spaces and last through hard use.

Flexible hoses are simple to put in and move.

Tough hoses save money because you do not replace them often.

Cost is important when you choose a hose. Some materials, like PTFE, cost more but last longer and resist more chemicals. Rubber hoses are cheaper but may not last with strong chemicals. Think about how long the hose will last, not just the price. A hose that lasts longer and needs fewer fixes saves money over time. Always balance cost, performance, strength, and safety. For tough jobs, buy strong hoses like Honestflex to meet rules and avoid big problems.

Hose Material | Cost Level | Performance and Durability |

|---|---|---|

PTFE | Highest | Superior durability, chemical resistance, and temperature tolerance |

Rubber | Lowest | Inexpensive, but lower durability with harsh chemicals |

PVC | Moderate | Good for basic jobs, but less durable for heavy-duty applications |

When you move acids, you need hoses that do not react. Some hose materials work better for acids than others.

UHMWPE hoses can handle strong acids and last a long time.

PTFE hoses give the best protection, even with harsh acids.

Composite hoses have layers that stop acid and stay bendy.

Special acid hoses use synthetic rubbers or thermoplastics for more safety.

These materials help stop leaks and damage. Many companies use them because they do not break down fast.

Solvents can damage hoses if you pick the wrong one. You need hose materials that do not react or wear out quickly. Here is a table to help you choose:

Material | Key Properties | Main Advantages |

|---|---|---|

UHMWPE | Broad chemical resistance, high abrasion resistance | Durable, smooth transfer, non-toxic |

XLPE | Exceptional solvent resistance, impact strength | Handles many solvents, strong build |

FEP | Chemical inertness, high-temp resistance | Works with aggressive solvents |

EPDM (Cover) | Weather and chemical resistance | Protects hose, adds safety |

These hose materials help you move solvents safely. They also help your hose last longer.

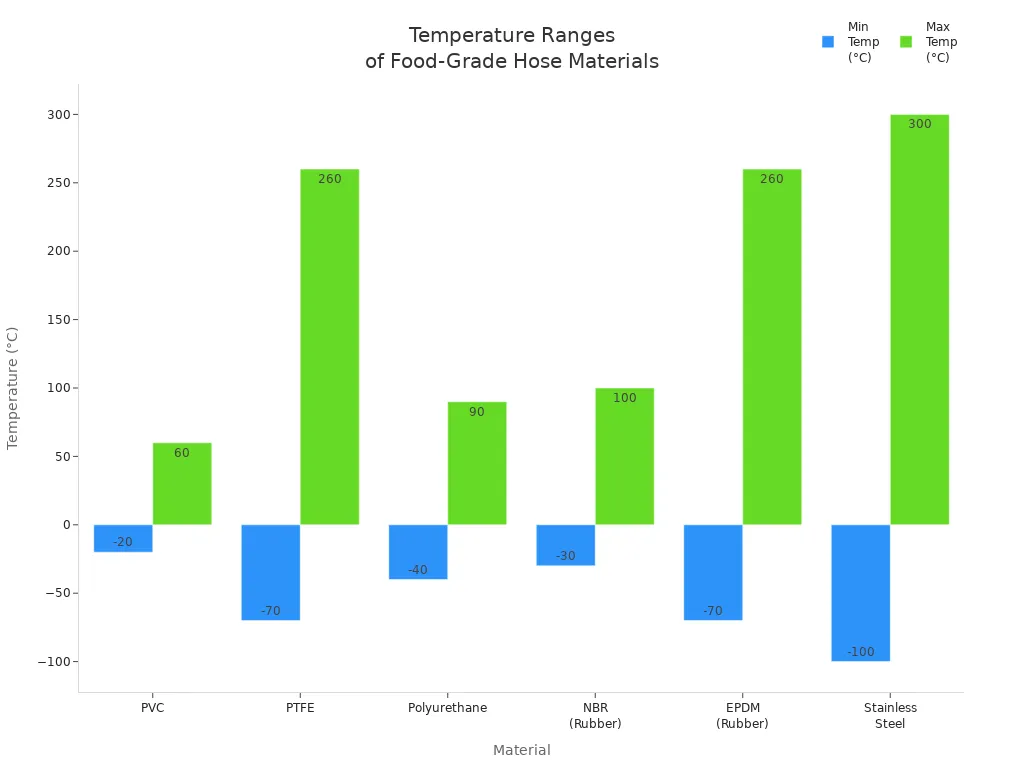

Food-grade hoses must follow strict rules. The hose material should not change the taste or smell of food. It must also work in hot and cold places. Here is a chart showing temperature ranges for food-grade hose materials:

PTFE and EPDM are good for drinks, juices, and alcohol. Polyurethane works well for dry foods. Stainless steel is best for very hot jobs. Honestflex hoses use UHMWPE and EPDM. These hoses meet FDA, USDA, and 3-A rules. This keeps your food safe and your work clean.

Factories and plants need hoses that can take pressure and rough use. Honestflex hoses use strong materials that resist pressure. They work in tough places like chemical plants, mines, and oil fields. The two layers and wire inside keep the hose safe and steady. You get safe liquid transfer and fewer leaks. Honestflex hoses also meet industry rules, so your team stays safe and you follow the law.

Picking the right chemical suction hose material keeps you safe. Every material has good and bad points. PTFE can handle strong chemicals. Rubber is easy to bend. You should always pick a hose that fits your chemicals and job.

Tip: Look at compatibility charts and ask experts before buying.

If you need more safety or must follow strict rules, try advanced hoses like Honestflex. These hoses give strong protection and meet industry standards.

You should choose the material based on the chemicals you handle. UHMWPE and PTFE work well for most acids and solvents. EPDM is good for water-based chemicals. Always check a compatibility chart before you decide.

Look for hoses that meet FDA, USDA, or 3-A standards. Honestflex’s Chemical Suction Hose meets these rules. You can use it for food, drinks, and sensitive products.

No, you should not use one hose for every chemical. Some chemicals can damage certain materials. Always match the hose material to the chemical you move. This keeps you safe and prevents leaks.

Check your hose often for cracks, swelling, or leaks. Replace it if you see any damage. Most hoses last several years, but harsh chemicals or rough use can shorten their life.

Honestflex uses UHMWPE inside for strong chemical resistance. The EPDM cover protects against weather and wear. This dual-layer design gives you a hose that lasts longer and works safely in many environments.