English

T: +86-19511798062

E: sales@honestflex.com

E: sales@honestflex.com

Licang District, Qingdao, Shandong, China

Views: 0 Author: Site Editor Publish Time: 2025-08-05 Origin: Site

A sand blast hose is a special hose made to move abrasive materials very fast during sandblasting. This hose is very important for cleaning surfaces, getting metal ready, and fixing things in factories. Workers use a sand blast hose for hard jobs because regular hoses break too fast. Picking the right hose makes the job safer and helps it work better. The hose is strong, so it does not leak and can handle tough places.

A sand blast hose quickly moves rough materials to clean surfaces safely and well. These hoses have strong inside tubes, many fabric layers, and hard outside covers to stop damage and handle high pressure. Sand blast hoses are not like normal hoses because they can handle rough stuff, high pressure, and static electricity safely. Picking the right hose size and material keeps the pressure even and helps finish work faster without breaking things. Checking, cleaning, and storing the hose often makes it last longer and keeps people safe.

A sand blast hose is made for moving rough materials fast. Workers use this hose to clean or get surfaces ready. It can handle things like sand, steel shot, or grit. These materials move through the hose with strong pressure. They help take off rust, paint, or dirt from metal, stone, or concrete.

The Honestflex Sandblast Hose is a strong and trusted choice. It has a thick natural rubber tube that does not wear out fast. This hose works well for many jobs, like cleaning metal or fixing buildings. Using the right hose helps workers finish faster and stay safe.

There are different kinds of abrasive sandblasting hoses. Some have two layers for more strength and bending. Others have four layers for even more power and to handle higher pressure. Both types last longer than normal hoses when used for sandblasting.

Tip: A bigger hose at the start can help stop wear and keep the abrasive moving well.

Every abrasive sandblasting hose has three main parts. Each part helps make the hose strong and safe for sandblasting.

Component | Function |

|---|---|

Inner Tube | Lets abrasive materials flow and stands up to rough stuff. |

Reinforcement Layer | Makes the hose strong and helps it keep its shape under pressure. |

Outer Cover | Guards the hose from cuts, sun, and chemicals. |

The Honestflex Sandblast Hose has a black, smooth natural rubber tube inside. This tube does not wear out fast and helps the hose last longer. The hose has layers of strong fabric to make it tough and stop kinks. The outside is made from strong synthetic rubber. It keeps the hose safe from weather and rough use.

Lab tests, like the DIN Abrasion Tester and NBS Abrasion Tester, show how well rubber stands up to wear. These tests check how much rubber is lost when rubbed on rough things. Lab tests help compare hoses, but real jobs show how long a hose will last. Good hoses, like ones made from new natural rubber, can last 400 to 500 hours in normal sandblasting.

Sandblast hoses are not like regular hoses. They are made to move rough materials fast. The inside uses special rubber that does not wear out from sand or grit. The hose has extra layers called plies made from strong fabric or wire. These layers help the hose handle high pressure and keep its shape.

Regular hoses do not have these special parts. They may not have liners that stop wear or extra strong layers. Most regular hoses cannot handle sandblasting. They might break, wear out fast, or cause safety problems.

Sandblast hoses also have anti-static parts. This means they can move abrasive materials without making static electricity. The Honestflex Sandblast Hose has a tube that stops static to keep workers safe. Its strong design stops kinks and keeps the abrasive moving.

Note: Picking the right abrasive sandblasting hose helps workers finish jobs safely and fast. The inside size of the hose matters too. A bigger hose at the start helps stop wear and keeps the abrasive moving.

Sandblast hoses, like the Honestflex model, are made for hard jobs. They last longer, keep workers safe, and help make surfaces clean and smooth. Regular hoses cannot do as well in abrasive sandblasting hose jobs.

A sandblast hose plays a key role in every sandblasting machine. The hose connects the blast pot to the nozzle. It moves abrasive material and compressed air from the machine to the surface that needs cleaning or finishing. The hose must handle high pressure and rough materials without breaking or leaking.

Operators rely on the hose to keep the abrasive flowing smoothly. If the hose bends or kinks, the flow stops, and the job slows down. The Honestflex hose resists kinking, so workers can move around corners or reach tight spots. Its flexible design helps operators work faster and safer.

The hose must also protect workers from static electricity. When abrasive material moves quickly through the hose, it can build up static. The Honestflex hose has a static-conductive tube. This feature safely removes static, lowering the risk of sparks or shocks.

A sandblast hose must be strong and flexible. It needs to last through many hours of blasting. If the hose fails, the sandblasting machine cannot work. The right hose keeps the system running and helps workers finish jobs on time.

Tip: Always check the hose size before starting a job. The inside diameter should be three times the size of the blast nozzle. This keeps pressure high and blasting efficient.

A good sandblast hose also helps keep pressure steady. If the hose is too small, pressure drops, and the blast loses power. Operators may see poor results or need more time to finish. Using the correct hose size and type improves both safety and efficiency.

The sandblasting process uses a sandblasting machine, a blast pot, a hose, and a nozzle. The machine stores abrasive media, such as sand or steel shot, in a sealed chamber called the blast pot. Compressed air from an air compressor pressurizes the pot. Valves control how much abrasive enters the air stream.

The blast hose carries the mix of air and abrasive from the pot to the nozzle. The pressure inside the hose can reach up to 100 psi or more. Some jobs need even higher pressure, so the hose must be rated well above the working level. The Honestflex hose supports up to 174 psi, making it safe for tough jobs.

There are two main types of sandblasting systems:

In a siphon system, compressed air creates a vacuum. This vacuum pulls abrasive into the blast gun, mixes it with air, and pushes it through the hose.

In a pressure system, the blast pot is pressurized. The abrasive is metered into the hose and pushed by air through the nozzle.

Both systems rely on the hose to deliver the abrasive at high speed. The blast nozzle focuses the stream onto the workpiece. The abrasive hits the surface, removing rust, paint, or dirt.

A strong hose, like the Honestflex model, stands up to the constant impact of abrasive particles. Its thick rubber lining and reinforced layers prevent wear and bursting. The hose stays flexible, even in cold or hot weather, so operators can use the sandblasting machine year-round.

Note: Without a reliable sandblast hose, the entire blasting process stops. The hose must handle pressure, abrasion, and movement to keep the job going.

A sandblast hose is more than just a tube. It is a vital part of the sandblasting machine. It keeps the abrasive moving, protects workers, and ensures every blast is strong and even.

A good abrasive sandblasting hose must last through hard jobs. The hose gets hit by sand or steel shot all the time. Thick rubber inside the hose stops it from wearing out fast. Strong fabric layers, like two or four, make the hose tough. More layers help the hose last longer and keep its shape. This is important for sandblasting in rough places.

The Honestflex sandblast hose has a natural rubber tube that does not wear out fast. Its outside cover protects it from bad weather and rough ground. This keeps the hose from cracking or breaking, even after lots of use. The size of the hose matters too. The inside should be three to four times bigger than the nozzle. This helps stop wear and keeps the pressure strong at the nozzle. Shorter hoses from the blast pot to the work area help keep pressure high and stop extra wear.

Industry rules, like ISO 3861:2008, tell how to build these hoses. The table below lists important features:

Feature | Details |

|---|---|

Reinforcement | 2-ply or 4-ply textile layers |

Abrasion Resistance | DIN 53516: Max loss ≤ 60 mm³ |

Working Pressure | Up to 12 bar (174 psi for Honestflex) |

Burst Pressure | Up to 36 bar (522 psi for Honestflex) |

Temperature Range | -40℃ to +70℃ (-40℉ to +158℉) |

Checking and cleaning the hose often helps it last longer and keeps blasting safe.

A flexible abrasive sandblasting hose lets workers move around corners easily. The Honestflex hose bends but does not kink, so sand flows well. This makes each job faster and easier for workers.

Safety is very important in sandblasting. The hose must handle high pressure and not burst. Honestflex hoses use special rubber to stop static electricity. This keeps sparks from happening when sand moves fast. The outside cover made from synthetic rubber keeps the hose safe from weather and ozone.

A good abrasive sandblasting hose is strong, bends easily, and is safe. These things help workers clean and get surfaces ready without worrying about the hose breaking or being unsafe.

Picking the right size and material is very important. The hose size changes how much pressure you lose. Bigger hoses help keep the pressure strong. The hose should be at least three times bigger than the nozzle. If you need to go far or use high pressure, use a bigger hose. The size of your project and the abrasive type matter too. Cleaning a big ship may need a 1/2 inch or bigger hose. If you work with glass, a 1/4 inch hose is enough.

The hose material changes how well it works and how long it lasts. Rubber hoses bend easily and do not wear out fast. Some hoses have extra fabric or steel wire for more strength. Polyurethane covers protect the hose from wearing out. Honestflex hoses have thick rubber tubes and strong fabric layers. This makes them good for hard jobs.

Hose Material / Feature | Performance Impact in Abrasive Environments | Longevity Considerations |

|---|---|---|

Rubber | Flexible, abrasion resistant; suitable for general use | Degrades under UV and ozone exposure, lower pressure rating |

Polyurethane Outer Cover | Superior abrasion resistance, ideal for sand blasting | Protects hose from wear, extends service life |

Steel Wire Reinforcement | Enhances pressure capacity and durability | Reduces flexibility; choice of steel affects abrasion and kink resistance |

Pressure ratings help keep workers safe and the hose working well. Heavy-duty sandblast hoses can handle 150 to 174 psi. The burst pressure should be three times higher than the working pressure. Honestflex hoses can handle up to 174 psi and burst at 522 psi. Always pick a hose with the right pressure for your job. The right rating stops the hose from breaking and keeps everyone safe.

Hose Type | Pressure Rating (PSI) | Burst Ratio (Safety Factor) | Temperature Range (°F) | Description |

|---|---|---|---|---|

Heavy Duty 4-Ply Sandblast Hose | 150 | 3:1 | -40 to 180 | Four-ply construction for durability; abrasion resistant tube for harsh abrasive materials. |

Honestflex Sandblast Hose | 174 | 3:1 | -40 to 158 | Multi-ply fabric reinforcement, static-conductive tube, abrasion-resistant cover. |

Taking care of your blast hose helps it last longer and keeps you safe. Check the hose often for cracks, bulges, leaks, or soft spots. Clean the hose after every use to get rid of dust. Store hoses in a cool, dry place away from the sun. Put caps on the ends to keep out dirt and bugs. Do not bend the hose sharply or drag it on rough ground. Change the hose if you see any damage. Checking and cleaning the hose often helps stop problems and keeps blasting safe.

Tip: Always look for damage before you use the hose. Fixing small problems early keeps you safer.

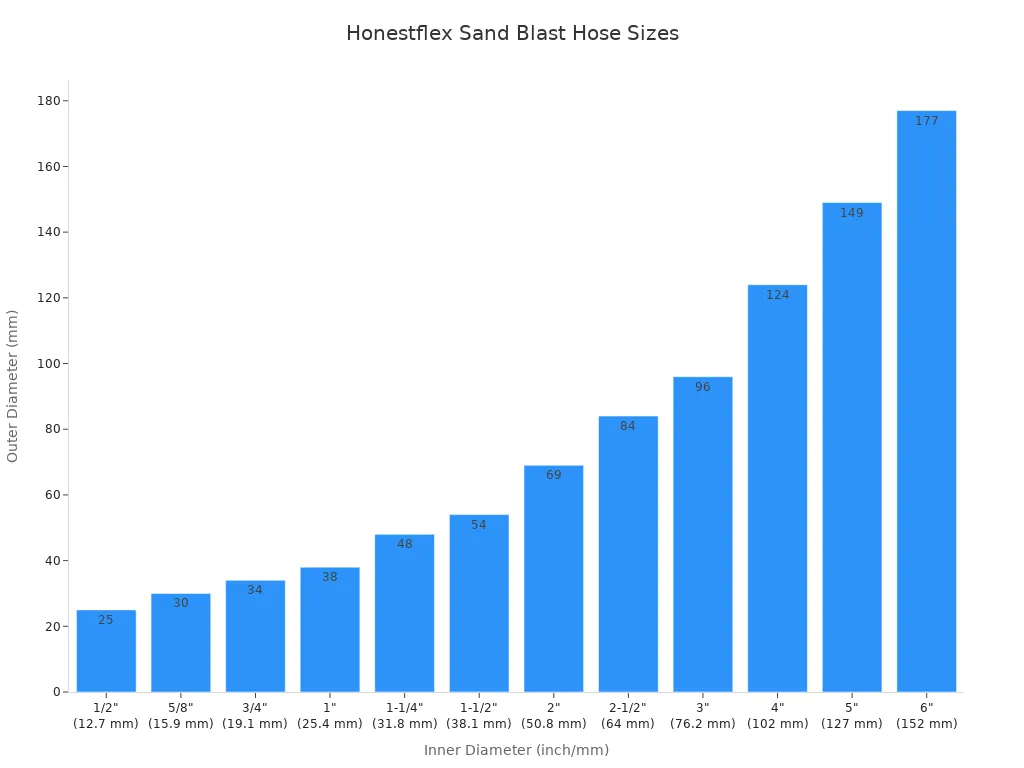

Honestflex has many hose sizes, from 1/2 inch to 6 inches. Their hoses are strong and built for tough jobs. Picking the right hose and following these tips helps you get good results and keeps your equipment safe.

A sand blast hose carries abrasive materials very fast. It helps clean or get surfaces ready. Picking a strong hose keeps workers safe. It also helps finish jobs quicker. Look for hoses with tough inner tubes. Make sure they have strong layers inside. The cover should not wear out or get damaged by weather. Check and clean the hose often to stop damage. This keeps blasting safe for everyone. Honestflex makes good hoses for big sandblasting jobs. Their hoses help workers do the job well.

A sand blast hose uses thick, abrasion-resistant rubber and strong fabric layers. This design helps it handle rough materials and high pressure. Regular hoses do not have these features and wear out quickly during sandblasting.

Workers should check the hose before every use. Look for cracks, bulges, or soft spots. Regular inspections help prevent accidents and keep the hose working safely.

Yes. A sand blast hose, like the Honestflex model, can move sand, steel shot, grit, or other blasting media. Its tough inner tube resists wear from many types of abrasive materials.

Store the hose in a cool, dry place away from sunlight. Use caps on the ends to keep out dust and insects. Proper storage helps the hose last longer.

Static electricity can build up when abrasive materials move fast. This can cause sparks. A static-conductive hose, such as Honestflex, safely removes static and lowers the risk of fire or shock.